Your power generation petrochemical resource

Technical expertise in valve refurbishment, procurement, modifications, design and general machining and manufacture. We provide an extensive range of valves for power generation, oil and gas, petrochemical, process, water and general industries.

Pressure Lube continues to bring customers a superior service of products.

Onsite Services

In-house actuation and automation fitting and testing of new products. Modify products as required to suit client q/a standards and specific needs.

Design Manufacture

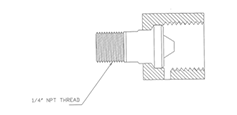

Supply Cad drawings that illustrate schematic piping arrangements. Specialist oxygen service cleaning and certification.

Product Range & Manufacturers

Specialist painting, sub-sea, spark holiday testing. Pre-test and recertification of new valves. Tagging, packaging and logistics

PRESSURELUBE

Health & Safety Policy

Pressure Lube is committed to protecting the health & safety of its employees, clients and others who may be affected by the activities of our company. To accomplish this, we take every effort to maintain a suitable working environment.

PRESSURELUBE

Service Report Checklist

We provide all our customers with a “service report checklist”, that records all valve statistics, valve tags with product number according to its corresponding drawing.

If maintenance crew observe additional work is necessary on both the ball valves and the wellheads, routine work is carried out first, before information can be gathered on future non-routine tasks.

PRESSURELUBE

Wellhead Maintenance

The objective of the Wellhead maintenance system is to provide and/or improve:

- Accountability

- Traceability

- Cost saving

- Safety awareness

- Wellhead integrity

24 hour call out

for offshore/onshore service.

PressureLube products, equipment and personnel are on stand-by and available 24 hour a day, 7 days a week.